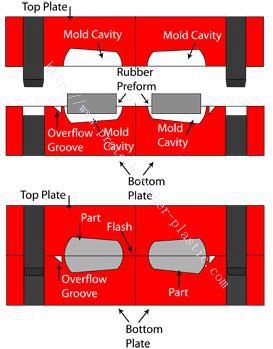

Molded /Compression Molding is one of the simplest and least expensive ways to produce molded rubber parts. While it is not typically recommended for complex parts requiring tight tolerances or flawless finishes, it is very cost effective method formanufacturing lower volume items. Typically the preheated rubber is placed into an open heated mold cavity. The mold is closed and pressure is applied forcing the material to thoroughly cover the mold cavity. Constant heat and

pressure are maintained until the material cures.

Qingdao Protech molding press capabilities for our compression line range from 100MMx 100MM on the low end, up to and including 2000 x2600MM on the high end, with various press sizes in between.

Advantages of compression molding

Inexpensive tooling

Less compound waste

Short setup time(saves on short proudction runs)

Good choice for large parts

Good for low production quantities

Good for high durometer parts

Disadvantages of Compression molding

Longer loading and process time

Labor intensive finishing

Heavier flash resulting in possible quality / tolerance issues